Stamping & Bending Line

Stamping Line – 30 to 200 Ton Capacity

Our stamping department features a full range of mechanical presses from 30 tons to 200 tons, suitable for both single-stage and progressive die stamping.

We operate a fully automated stamping line equipped with:

- Coil feeder and decoiler system

- Automatic servo transfer system

- Robotic arms for pick & place handling

- Safety and precision monitoring sensors

This system allows us to perform continuous, high-speed production of components such as brackets, frames, and precision motorcycle parts.

CNC Bending & Press Brake Machines

For metal forming and bending, we utilize:

- A 160-ton hydraulic press brake for large and thick components

- Multiple high-end CNC bending machines, offering tight bending tolerances and complex angles

- Skilled operators and offline programming for quick setup and consistent results

Our CNC bending equipment is ideal for producing custom brackets, enclosures, racks, and furniture frames with clean finishes and high repeatability.

Why Choose Our Metal Forming Line?

- Wide capacity range: from thin sheet to heavy gauge materials

- Automated production reduces labor cost and increases consistency

- Fast lead times for both small and high-volume orders

- Proven experience in OEM/ODM manufacturing for global clients

Laser cutting & Welding

High-Power Laser Cutting – Sheet & Tube

Our laser cutting division is equipped with both flatbed laser machines and tube laser cutting systems, with power ranging from 3kW to 6kW. This setup enables fast, clean, and precise cuts on a wide range of materials and thicknesses.

- Flatbed Laser Cutting Machines: Ideal for sheet metal components of all shapes and sizes

- Tube Laser Cutting Machines: Designed for high-precision cutting of round, square, and irregular pipes

- Cutting Tolerance: ±0.1mm

- Material Supported: Carbon steel, stainless steel, aluminum, and more

Our laser systems allow for custom patterns, clean edges, and zero secondary processing, optimizing both quality and production time.

Welding – Skilled Craftsmanship & Robotic Precision

We operate two dedicated welding workshops, meeting both manual and automated welding needs.

Manual Welding Workshop

- Experienced welders with over 15 years of hands-on expertise

- Proficient in MIG welding and handheld laser welding

- Suitable for small-batch, high-mix, and custom parts requiring fine detail and aesthetic finishes

- Application areas: motorcycle parts, decorative brackets, interior frames

Robotic Welding Workshop

- 10 high-performance robotic welding arms in operation

- Perfect for large structural parts such as industrial racks, frames, and furniture

- Delivers consistent quality, high-speed production and repeatable accuracy

- Equipped with automated jigs and rotation tables for efficiency

Why Our Cutting & Welding Stands Out

- Wide range of materials and thicknesses supported

- Fast lead times with in-house machining, cutting, and welding

- Combination of human expertise + robotic precision

- Ideal for OEM/ODM customers seeking both flexibility and large-scale production capacity

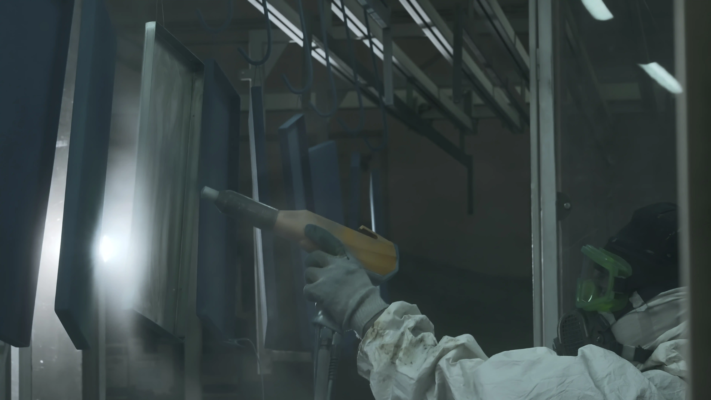

Surface Coating – In-House Finishing for Maximum Quality Control

Two Coating Lines: Powder Coating & Water-Based Paint

We provide both powder coating and water-based painting solutions in-house:

- Powder Coating Line: Ideal for durable, scratch-resistant finishes on steel racks, frames, and industrial parts

- Water-Based Paint Line: Suitable for thinner coatings and custom color applications for interior items

Both lines are equipped with large-capacity drying ovens, enabling efficient processing of large-size products such as home furniture racks, shelving systems, and steel enclosures.

Surface Preparation – Sandblasting or Chemical Pre-treatment

Before coating, all parts undergo thorough surface preparation, based on material and end-use requirements:

- Sandblasting: Removes rust, mill scale, and creates an ideal surface profile for coating adhesion

- Chemical Pre-treatment (Degreasing, Phosphating): Ensures clean, oil-free surfaces and enhances corrosion resistance

This meticulous prep work ensures a strong bond between metal and coating, delivering long-lasting and aesthetic results.

Your Coating Advantage – Fully Controlled, Fully Integrated

- Faster sampling & product development

- Better color consistency and finish quality

- Complete quality control from raw material to final surface

We are especially experienced in finishing products for export markets where coating durability and appearance are key to customer satisfaction.

Applications:

- Industrial and warehouse racks

- Home furniture frames

- Motorcycle and scooter accessories

- Brackets, panels, enclosures

Mold Design & Prototyping

Capabilities Include:

- Metal Stamping Dies: Progressive, compound, and single-stage dies for parts such as brackets, frames, and hardware

- Plastic Injection Molds: For functional components, covers, fixtures, or decorative parts

- 3D Printing Support: Quick prototyping using plastic 3D models for product evaluation and fitting tests

Design Software Expertise:

Our experienced engineers use advanced CAD/CAM tools including:

- AutoCAD – 2D drawings and layout

- Siemens NX – Complex surface modeling and die design

- SolidWorks – 3D part design and mold assemblies

This allows us to optimize the mold structure, reduce defects, and simulate part behavior before tooling.

In-House CNC Tooling Workshop

All molds are machined and assembled in our own CNC tooling workshop, equipped for high-precision milling, EDM, grinding, and fitting. This allows for:

- Faster turnaround – from drawing to mold in weeks

- On-site modifications and maintenance

- Full quality control and confidentiality

Why Choose Our Mold Services?

- Integrated with our stamping, injection, and welding lines

- Faster sample delivery and cost-effective development

- Ideal for OEM & customized projects with repeated demand

- One-stop service from concept → mold → production

Applications:

- Motorcycle accessories

- Storage brackets, clips, panels

- Plastic fixtures and covers

- OEM/ODM custom metal parts